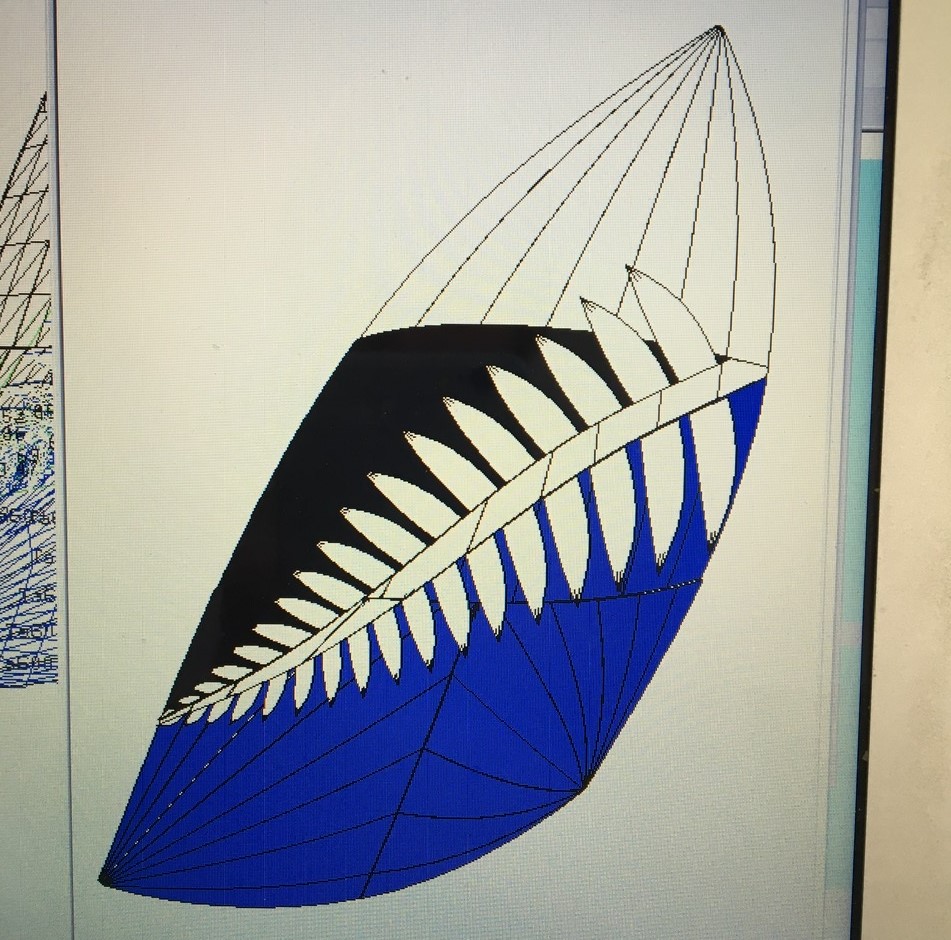

My former employer was commissioned by the International Olympic Committee (IOC) to create asymmetric spinnakers featuring the country flag of the respective team sewn into the sail during manufacturing. The criteria stated that the sails needed to be equal in shape and weight, so as not to give any advantage to simple flag designs or disadvantage to more complex flags. I was tasked to come up with a technique to make this possible and produced a successful proof of concept sail. This process created highly complex panel design files and required a new tool to generate a seam allowance file.

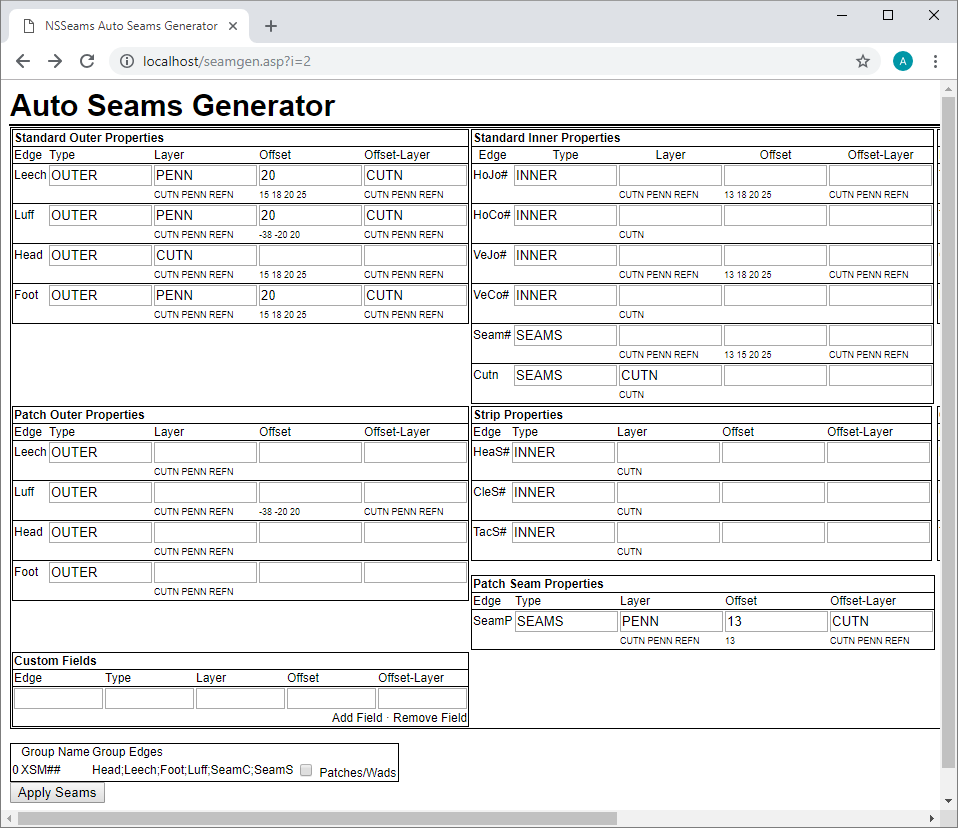

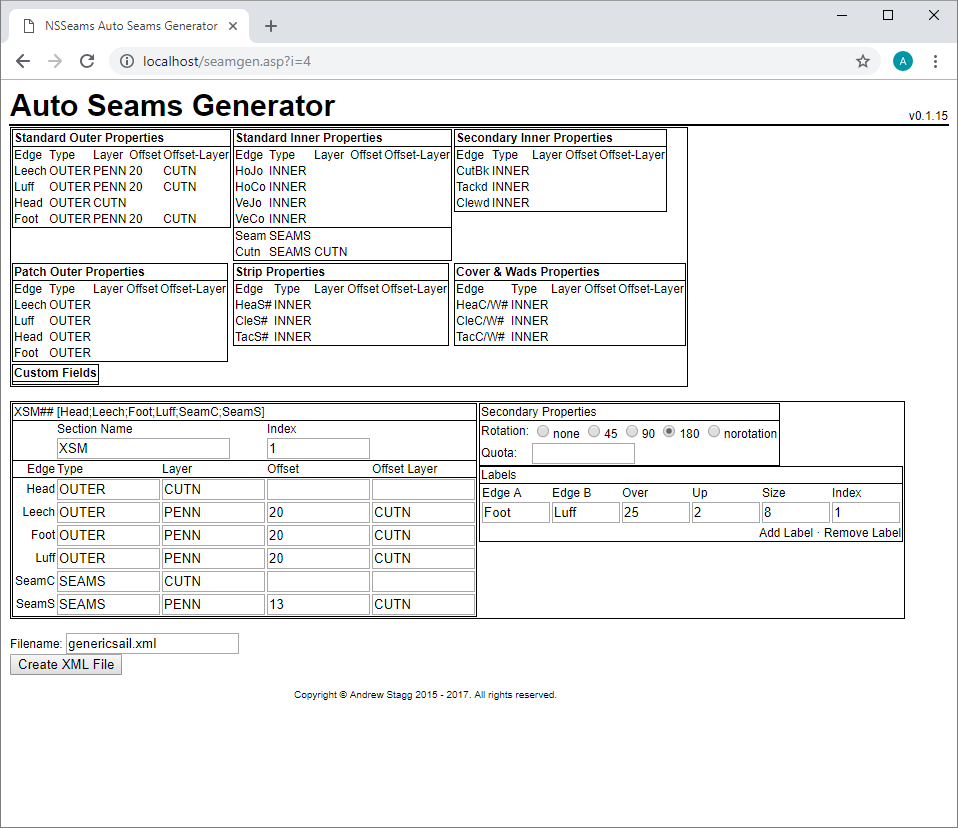

Auto Seams Generator is the result of needing to apply seam allowance values to hundreds of uniquely named edges (seams) in extremely complex design files. Using a keep it simple approach, I developed a web-based ASP Classic wizard-style application with the goal of reducing the time it took to process custom sails and deliver the sails to the Olympics on time.

The core functionality of this wizard matches the process that would have been applied by a designer using traditional methods but in an automated and standardized way.

Design files are copied into the wizard and then parsed to extract the panel groupings along with edge and seam names. This information was displayed out to the designer to confirm or rearrange before moving on to the next step. The groups, edges, seam names were separated into two groups- one containing standard names, and another mismatch group. The mismatches were further processed to expose any intentional naming convention. Both groups were then displayed out for the designer to assign values and rotation constraints.

The automated edge name processing was really the key to making this tool invaluable. Reading all the edge names ensured that all edges of any given panel would be recognized and a value could be assigned to them. Assigning values was streamlined with a”Click-To-Fill” feature, which displayed common values below the individual fields. Another benefit from the automation was the ability to enforce requirement rules on edges. Between discovering all edge names and requiring they had a value, the time it took to produce a custom seam allowance file was drastically reduced from hours of typing and verifying to well under 10 minutes.

Ultimately the results were saved to an XML file which was 100% compatible with the traditional tooling, as well as being able to be read into PatternSmith for post-processing and nesting.

Without this wizard, the 2016 Rio Olympic 49er Fx asymmetric country flag spinnakers would not have been feasible. A total of 11 unique custom layouts were created for 20 countries, resulting in around 100 sails built for the 2016 games.

As a result of defining a standard set of edge names for the Auto Seams Generator, I was able to standardize how new or custom panel design files were made by other designers. Creating these conventions helped reduce complexity and increased the ability to share each individual’s work.

Auto Seams Generator was developed as a personal side project. While used by myself at my previous employer, the previous employer did not commission nor own rights to the code base. Data shown was created randomly for demonstration and does not portray intellectual property.