Mimic Studio was developed to standardize a new process and decrease the time a designer spent reverse engineering 2D legacy design. Until the creation of Mimic Studio designers did not have a clear path to modernizing legacy designs; this often lead to a trial and error process of making multiple iterations of R&D sails, and little data to validate the results. Creating a standard process which designers could follow allowed for fewer R&D sails and predictable results.

It was also a personal goal to learn a more modern language and architecture than Visual Basic 6.0, which I had previously used in the early 2000s. So this project represents my transition into the .NET Framework and C# with WinForms.

With rapid development, a core concept of this application, several features were developed to aid in the 2D pattern input process, the creation of preliminary design files, and presentation of comparison data.

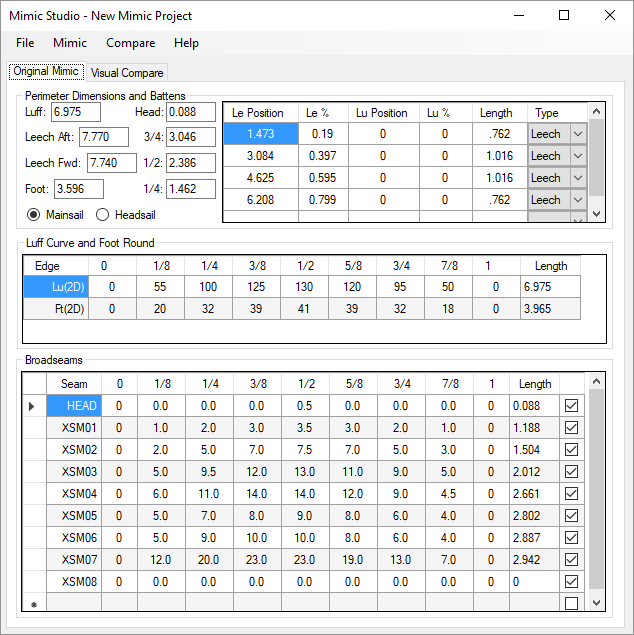

Time spent gathering the necessary information from a 2D pattern was reduced by designing a broadseam builder interface, which given all the individual pieces of a sail could then calculate the total values for each join or seam. This was critical, as it is the metric used for comparison to the new 3D design.

Together with the broadseam data, and a full 2D CAD measurement of the 2D pattern, Mimic Studio is able to generate starter shape, panel, and seam files which could then be loaded into the design software. These starter files contained the principal dimensions, batten locations, calculated parameter inputs for the shape, and seam locations that matched the original 2D pattern. Having these files automatically generated drastically cut the time it took for a designer to get started on the comparisons.

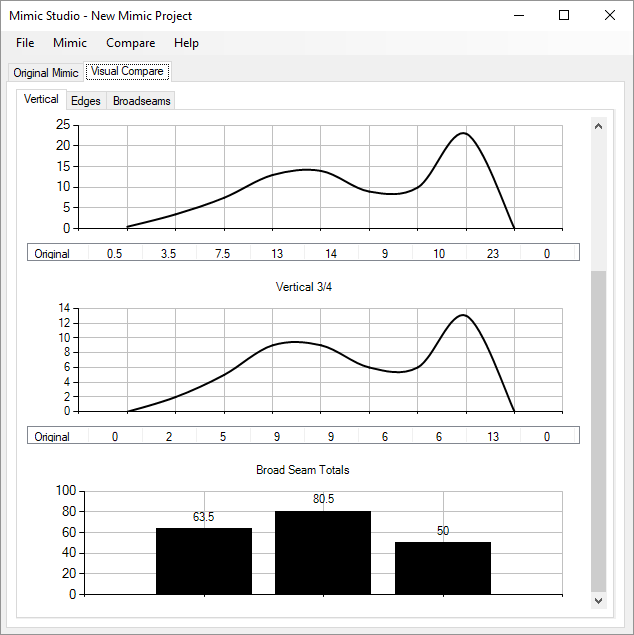

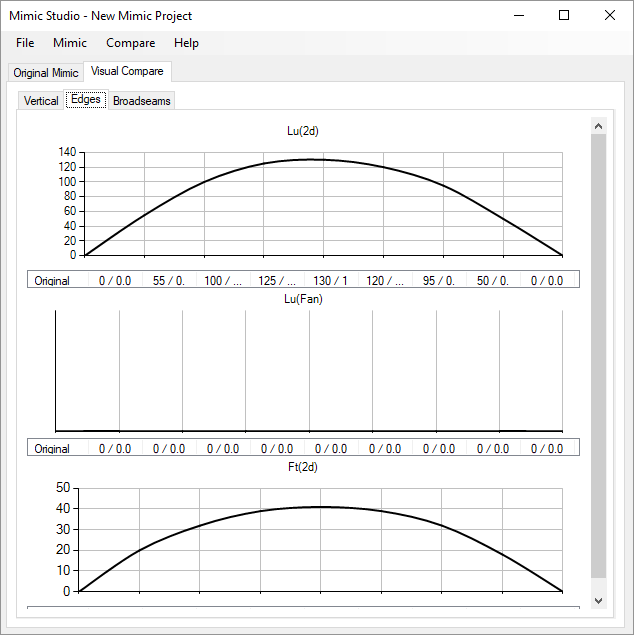

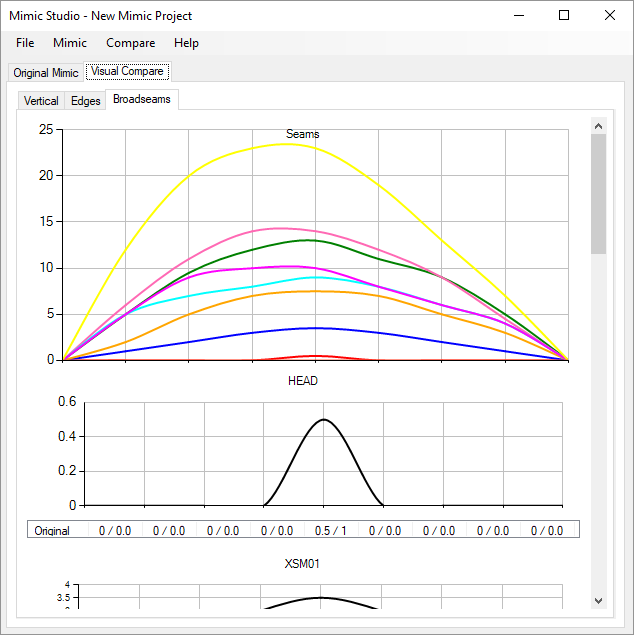

With the design files generated and run through the design software, Mimic Studio was able to read in and parse the output to create comparable data. Graphs and tables made it easy to understand and identify what changes needed to be made to the design files. Mimic Studio hooked the output files and updated itself as soon as a change was made allowing the designer to go through hundreds of iterations refining the 3D shape to match the 2D pattern.

Using this process, an R&D 3D design could be guaranteed to be within tenths of a millimeter to that of the original 2d legacy pattern. Typically a CAD comparison was also conducted to confirm that the resulting 3D design did indeed match the 2D pattern.

Over the course of development, additional features were added that allowed for direct comparison of 3D designs using the same graphs and tables. This allowed designers to confirm that changes flowed through to the resulting shape as intended, without the need to set up sophisticated computer modeling.

Patterns emerged as more projects utilized Mimic Studio; we were able to study these patterns and apply them to issues displayed in the production sails. Often times this lead to the resulting Mimic Studio influenced design, to prove faster than the original 2D design. In certain classes, a proven winner might have held a top spot for decades via traditional sail development.

Taking advantage of the 2D-to-3D “mimc’ing process”, Mimic Studio was used to develop the 2017 Etchells World Championship winning mainsail. Prior to this achievement, a modern digital design had not won an Etchells World Championship.

Utilizing the 3D-to-3D comparison features, Mimic Studio once again proved itself invaluable in developing the 2017 J-70 North American winning mainsail. Previous J-70 designs had come from initial computer modeling of the boat, spars, and sails, so improving this particular design was quite rewarding.

Mimic Studio was developed as a personal side project. While used by myself during my former employment, the previous employer did not commission nor own rights to the code base. Data shown was created randomly for demonstration and does not portray actual design information.